Machine Monitoring - Wireless

PROCESS OPTIMIZATION SYSTEMS FROM WERMA USA

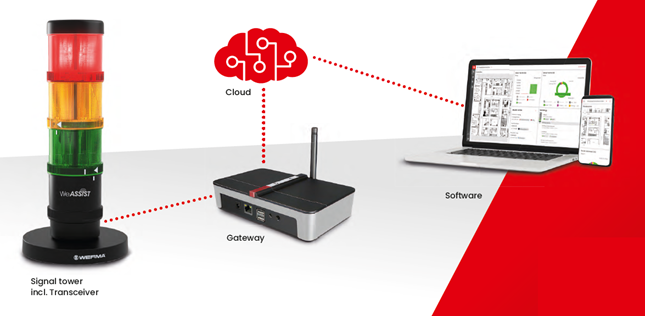

WeASSIST – Process optimization in one minute. Keep an eye on your business at all times – digitally and in real time. WeASSIST helps you identify problems before they arise and turns networking into an advantage that makes Industry 4.0 a reality.

WeASSIST is Werma’s evolution of the tried and true SmartMonitor technology bringing their machine monitoring solution into the world of mobile data. Now instead of needing direct access to your onsite data plant floor data from a connected PC at your facility, the WeAssist platform moves your plant floor information to the cloud meaning you can access it via a mobile phone, tablet, or other connected device.

Werma’s technologies represent modern industry’s smartest solutions for factories needing to get data out of existing machines.

WeASSIST enables notification-based alerts on mobile devices to inform operators and managers on:

- Machine errors and downtime

- Create and manage machine categories

- Material resupply requirements

- Productivity reporting by machine, by area, by building, and more

The WeASSIST solution’s subscription model and cloud-based technology frees your plant floor data from the restrictions your company’s IT department might impose. With secure communications between Werma WeASSIST Transmitters mounted at each machine (typically mounted with Werma KOMBISign72 signal towers, but also compatible with many other brands) and a Werma WeASSIST Gateway to manage the data connection to the cloud.

WeAssist Mobile App

You can download Werma’s WeASSIST mobile app for Apple or Android devices:

WeASSIST for Apple devices: https://apps.apple.com/us/app/weassist-werma-signaltechnik/id1574639714

WeASSIST for Android devices: https://play.google.com/store/apps/details?id=com.werma.weassist&hl=en&gl=US&pli=1