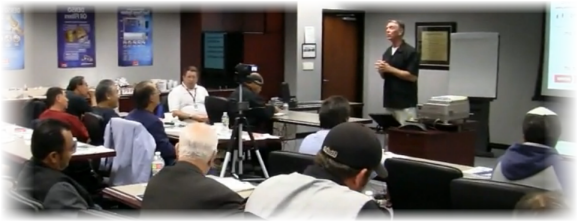

At Automation Southwest, we believe one of the strongest paths for growth we can offer is a local customer base with high caliber hands-on skills using our products. This basic idea applies to both our local distribution sales network and the OEM design engineers we work with across multiple industries who apply our technology to build working systems. To support this goal, we offer training in multiple product categories and in multiple formats:

Industrial Automation Components Training – OEM equipment builders rely on efficient application of the newest technologies to stay ahead of their competition. To ensure that our OEM partners have the competitive edge, ASW offers hands on product training on PLC’s, touchscreens, servo solutions, and much more. (IAC Training is heavily dependent on customers’ needs and each session is customized to maximize the time investment for the OEM design & engineering team)

Sensor Technology Training — New developments in sensing technology emerge at an impressive rate. Keeping informed of these new tools means investing time in training from Automation Southwest. We present the latest in laser-based and optical sensing for product detection, registration mark detection, and non-contact measurement. (Typically offered in a Lunch & Learn format at the customer’s site)

Safety Technology Training – Covering emerging safety tech such as RFID and programmable safety controllers, plus traditional components such as machine interlocks, light curtains, emergency stops, safety mats, and safety relays, this session gives both experienced personnel and individuals new to the industry an overview of the latest technologies to improve machine safety. (Typically offered as a one- to two-hour presentation; typically hosted at customer’s site)